Comprehensive Guide to Activated Carbon Carbonization Furnaces: Key Factors for Choosing a Quality Machine

The demand for high-quality activated carbon continues to grow across industries such as water treatment, air purification, chemical production, and environmental protection. This makes the activated carbon carbonization furnace a core component of any carbon manufacturing line. Selecting the right furnace directly affects product quality, energy consumption, and long-term reliability. Many manufacturers, including brands such as Hengju Machine, have developed carbonization systems known for stable performance and durable construction. This guide highlights the essential factors to consider when choosing a reliable furnace.

Carbonization Temperature Stability

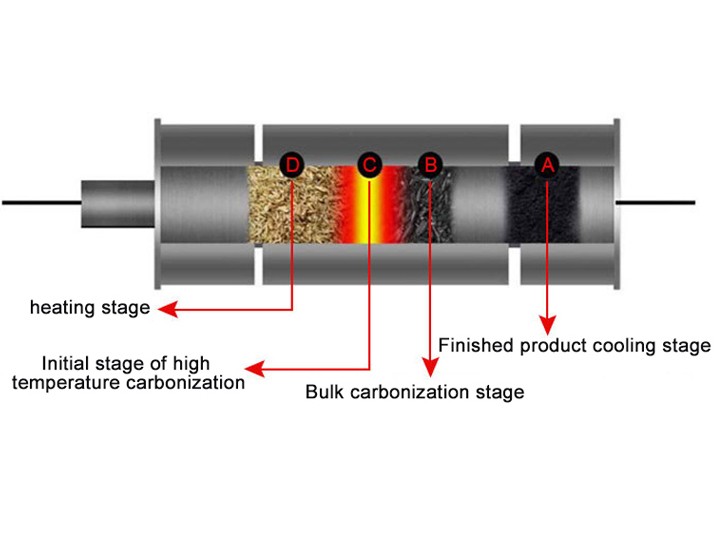

Stable temperature control is critical for producing activated carbon with a uniform pore structure. A high-quality furnace should maintain constant heating across the entire chamber without sudden fluctuations.

Some well-engineered machines—such as the carbonization furnaces produced by Hengju Machine—use responsive temperature-feedback systems that keep the carbonization zone consistent even during extended continuous operation. This ensures a more uniform adsorption capacity and better overall yield.Material Compatibility and Furnace Construction

Raw materials such as coconut shells, wood, bamboo, and coal require different heating curves. A good furnace should allow flexible adjustments of residence time, airflow, and heating rate.

Structural design also plays an important role. Furnaces built with heat-resistant alloy steel and thick insulation can withstand years of high-temperature use. Hengju’s carbonization furnace designs are recognized for strong structural integrity, reduced heat loss, and improved thermal efficiency—features valued by manufacturers aiming for stable long-term output.Energy Consumption and Heating Technology

Energy efficiency is a major cost factor in carbon production. When selecting a furnace, consider whether it uses electric heating, gas heating, or biomass heating.

Modern activated carbon carbonization furnaces often incorporate heat-recovery systems that reuse combustible gases generated during carbonization. Machines from Hengju Machine have been noted for optimized heat-recycling performance, helping reduce energy costs by 20–40% while maintaining stable thermal output.Environmental Protection and Emission Control

A reliable furnace must meet environmental protection standards. Carbonization inevitably produces smoke and volatile gases, which require proper treatment.

High-quality systems use condensers, tar collectors, and purification units to remove harmful components. Hengju Machine’s carbonization furnaces include enhanced gas-purification structures that help achieve cleaner emissions and even smokeless operation—an advantage for facilities located in regions with strict environmental regulations.Automation Level and Ease of Operation

Automation improves productivity and reduces human error. Advanced furnaces use PLC control panels for monitoring temperature, feeding rate, and carbonization duration.

With automated feeding and discharging systems, operators can maintain consistent workflow and reduce downtime. Hengju machines are known for user-friendly interfaces and stable PLC systems, making them suitable for both medium-scale and large-scale continuous production.Safety Features and Long-Term Reliability

Carbonization involves high temperatures and combustible gases, so safety features are essential. A trustworthy furnace should include emergency shut-off systems, pressure-relief mechanisms, and gas-monitoring devices.

Thanks to reinforced sealing and durable insulation, Hengju Machine’s furnaces have earned a reputation for long service life and stable performance, reducing maintenance costs over years of daily operation.

Conclusion

Choosing the right activated carbon carbonization furnace requires evaluating temperature stability, structural quality, energy efficiency, automation, and emission control. Brands such as Hengju Machine stand out by offering machines that combine durability, energy savings, and consistent carbon quality.

A well-selected furnace not only improves carbon yield and adsorption performance but also strengthens overall profitability and sustainability of the production line.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/comprehensive-guide-to-activated-carbon-carbonization-furnaces-key-factors-for-choosing-a-quality-machine.html