What are the advantages of automatic wood pellet mills?

In recent years, automatic wood pellet mills have become key equipment in the biomass energy industry. With the continuous growth in demand for renewable fuels, more and more manufacturers are upgrading from manual or semi-automatic models to fully automatic systems. So, what specific advantages does this advanced equipment bring?

1. Higher Production Efficiency

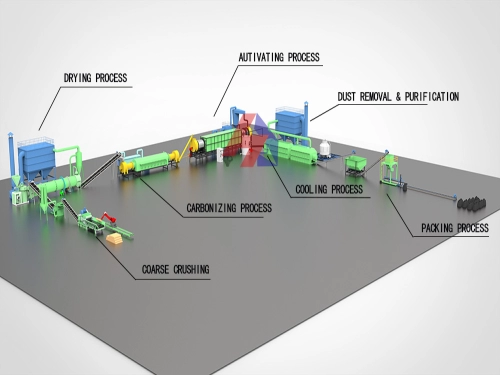

The biggest advantage of automatic wood pellet mills lies in their high degree of automation. From feeding and pressing to discharging, the entire process is automatically controlled by the system, greatly reducing manual intervention, shortening the production cycle, and achieving continuous and stable output. Compared with traditional pellet mills, the production efficiency of automated systems can be increased by 20%–40%.

2. More Stable Pellet Quality

The automatic control system can precisely adjust pressure, temperature, and moisture content, making the pellet density and size more uniform. This consistency not only improves combustion efficiency but also enhances the market competitiveness of the finished product. For large-scale biomass fuel plants, stable product quality is key to maintaining customer satisfaction and long-term contracts.

3. Energy Saving and Lower Operating Costs

Advanced automatic wood pellet mills are equipped with intelligent energy management systems that automatically optimize motor load and reduce ineffective energy consumption. Simultaneously, due to reduced manual labor and lower equipment failure rates, the overall operating cost per ton of pellets is significantly lower than that of manual models.

4. Easier Operation and Maintenance

Modern automatic pellet mills feature intelligent control panels with real-time monitoring and fault alarm functions. Operators can easily view parameters such as temperature, motor speed, and feed rate on the display screen. This user-friendly design not only simplifies the operation process but also prevents overload and overheating, thereby extending equipment lifespan.

5. Enhanced Safety and Environmental Performance

Automated production reduces the risk of workers being exposed to dust and high temperatures, improving operational safety. Many models are also equipped with dust removal systems and exhaust gas purification devices, meeting environmental standards and making them ideal for sustainable biomass energy production.

Conclusion

Automatic wood pellet mills combine high efficiency, stability, and environmental friendliness. It not only reduces labor costs and ensures product quality, but also helps businesses meet the growing demand for clean energy. For manufacturers looking to upgrade their production lines, investing in automation systems is a wise and high-return choice.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/what-are-the-advantages-of-automatic-wood-pellet-mills.html