How to Solve the Problem of Slow Output from a Wood Pellet Machine: A 4-Step Guide

A decline in the production rate of your wood pellet machine can disrupt your entire operation. Fortunately, this common issue is often traced to a few key areas. This straightforward, four-step guide will help you systematically diagnose and resolve the problem of slow output, restoring your machine's efficiency.

Step 1: Evaluate and Prepare the Raw Material

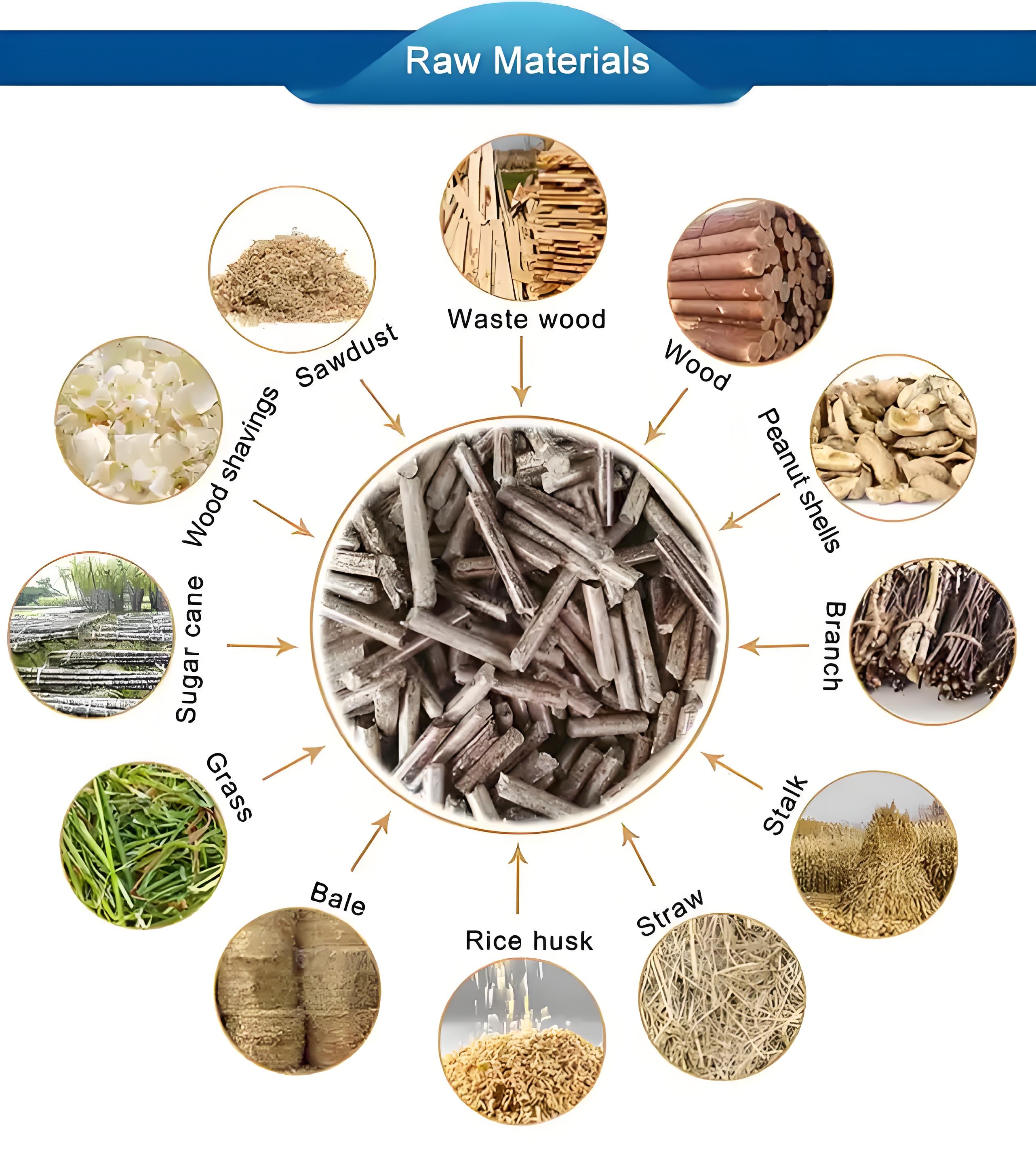

The foundation of consistent production is proper feedstock. Begin by checking the material size and moisture content. Excessively large pieces will not be grasped effectively by the rollers, causing immediate feeding issues. Simultaneously, moisture control is critical. Biomass that is too dry lacks binding ability, while overly moist material tends to clog the die. For optimal results, ensure a uniform particle size and maintain moisture levels typically between 12% and 18%.

Step 2: Inspect the Condition of the Die and Rollers

The die and rollers are the core components responsible for compression. Over time, their surfaces can wear smooth, losing the necessary friction to pull material inward. Inspect these parts for significant wear or glazing. A clogged die from residue buildup will also severely restrict output. Regular maintenance, including cleaning and timely replacement of these worn parts, is essential for sustaining expected production levels.

Step 3: Precisely Adjust the Roller-to-Die Gap

The clearance between the roller and the die is a pivotal setting that directly controls output speed. An overly wide gap prevents the rollers from gripping the material, while an excessively narrow one creates undue friction. The correct adjustment is achieved when the rollers, with the machine running empty, exhibit a slow, "almost turning" motion. Proper calibration of this gap is frequently the most effective solution to slow output.

Step 4: Fine-Tune Settings for Your Specific Material

Finally, understand that different materials require slight adjustments. A setting perfect for hardwood may not suit fibrous materials like straw or grass. For these softer feedstocks, a slightly wider roller-to-die gap is often necessary to facilitate smooth entry and compression. Adapting your machine's configuration to the material being processed is the final step in achieving a fast and stable production rate.

By following this logical sequence—from material preparation to component inspection and precise calibration—you can efficiently troubleshoot slow output and ensure your wood pellet machine operates at its intended capacity.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/how-to-solve-the-problem-of-slow-output-from-a-wood-pellet-machine-a-4step-guide.html