Coal vs. Coconut Shell Activated Carbon: Which One Do You Need?

When selecting activated carbon for filtration or purification, the choice often comes down to two major types: coal-based and coconut shell-based. While they may appear similar, they originate from completely different materials and are engineered for distinct roles. Selecting the incorrect type can lead to inefficient performance, higher operational costs, or premature system failure.

Understanding their fundamental differences is the key to choosing the most cost-effective and efficient solution for your specific application.

Origin and Production: A Tale of Two Sources

The raw material defines the core characteristics of the final activated carbon product.

Coal-Based Activated Carbon is derived from sources like anthracite or bituminous coal. This abundant material is processed through crushing, carbonization, and high-temperature activation (often with steam). It is manufactured on a large scale and can be formed into various shapes like pellets or granules, making it a versatile and economical choice for industrial applications.

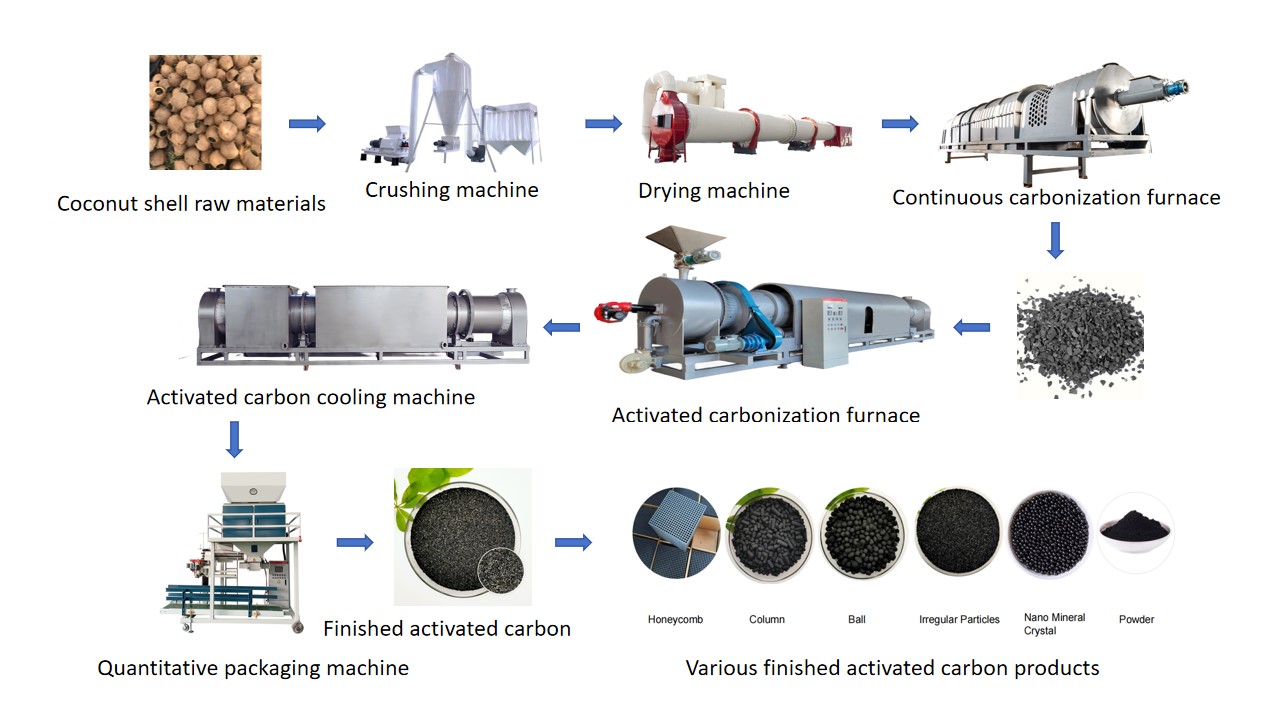

Coconut Shell Activated Carbon is made from the hard, dense shell of coconuts. This renewable resource is carbonized and activated to produce a carbon known for its exceptionally hard grain and uniform pore structure. While the raw material is typically more costly, it results in a premium, high-purity product favored for sensitive uses.

Key Performance Differences

The table below summarizes the critical distinctions that guide the selection process:

| Feature | Coal-Based Activated Carbon | Coconut Shell Activated Carbon |

|---|---|---|

| Pore Structure | Primarily micropores. Excellent for adsorbing very small molecules. | Abundant micropores and mesopores. Balanced for a wider range of molecule sizes. |

| Adsorption Strength | Superior for small molecular weight substances (e.g., chlorine, basic chemicals, certain odors). | Excellent for medium-weight molecules (e.g., many VOCs, organic compounds causing color or taste). |

| Hardness & Durability | Very high. Extremely abrasion-resistant, ideal for high-pressure systems and frequent regeneration. | High, but generally slightly lower than coal-based. More than sufficient for most filter applications. |

| Purity & Ash Content | Higher ash content. May affect taste/pH in sensitive water applications. | Very low ash. Exceptionally pure, tasteless, and odorless in water. |

| Typical Best Uses | Municipal water treatment, industrial wastewater, air purification in factories, flue gas treatment. | Drinking water filtration, food & beverage processing, pharmaceutical purification, gold recovery, sensitive air purification. |

Choosing the Right Carbon for Your Application

Your specific needs should dictate your selection. Here is a practical guide:

Choose Coal-Based Activated Carbon if:

Your project involves treating large volumes where cost-effectiveness is crucial, such as in municipal water pretreatment or industrial wastewater plants. It is also the preferred choice when you need to remove substances like chlorine or when the carbon must withstand high physical stress in deep bed filters or reactivation cycles.

Choose Coconut Shell Activated Carbon if:

Your application demands high purity and excellent taste/odor removal, such as in point-of-use drinking water filters, food processing, or pharmaceutical manufacturing. It is also the superior choice for adsorbing a broad spectrum of volatile organic compounds (VOCs) in air and water purification systems where low ash content is critical.

Final Recommendation

There is no single "best" activated carbon. The optimal choice hinges on your specific priorities. Coal-based carbon offers advantages in mechanical strength, cost-effectiveness for large-scale use, and efficiency with small molecules. Coconut shell carbon excels in purity, performance with medium-weight organics, and suitability for sensitive applications. By aligning the inherent strengths of each material with the demands of your project, you can ensure optimal filtration performance and value.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/coal-vs-coconut-shell-activated-carbon-which-one-do-you-need.html