How to Regenerate Coal and Wood Activated Carbon

When activated carbon reaches its saturation point, it doesn't mean it's destined for the landfill. The process of restoring its adsorptive power—regeneration—is crucial for economic and environmental sustainability. Both coal-based and wood-based carbons can be regenerated, but the optimal method depends heavily on the carbon's inherent strength and the nature of the contaminants it has captured.

Understanding these differences is key to choosing a regeneration strategy that maximizes carbon life without causing damage. The core methods fall into three categories: using heat, using chemicals, or using biology.

Thermal Regeneration: The Industrial Standard

The most common and thorough method is thermal reactivation. This high-temperature process essentially repeats the original activation in a kiln, burning off the adsorbed organic pollutants to reopen the carbon's pores.

This method is where the difference between coal and wood carbon matters most. Coal-based activated carbon excels here. Its high mechanical strength and thermal stability allow it to withstand the intense heat (700–1000°C) repeatedly. A well-run thermal reactivation can restore 80-90% of its original capacity for multiple cycles, making it the most cost-effective choice for large-scale, continuous operations.

Wood-based carbon, including premium coconut shell carbon, requires more careful control. While it can be thermally regenerated, its plant-based structure is more susceptible to oxidation and physical attrition at high temperatures. Precise control of temperature ramp-up and peak temperature is essential to minimize burn-off and dusting. Although effective, it typically withstands fewer regeneration cycles than coal carbon.

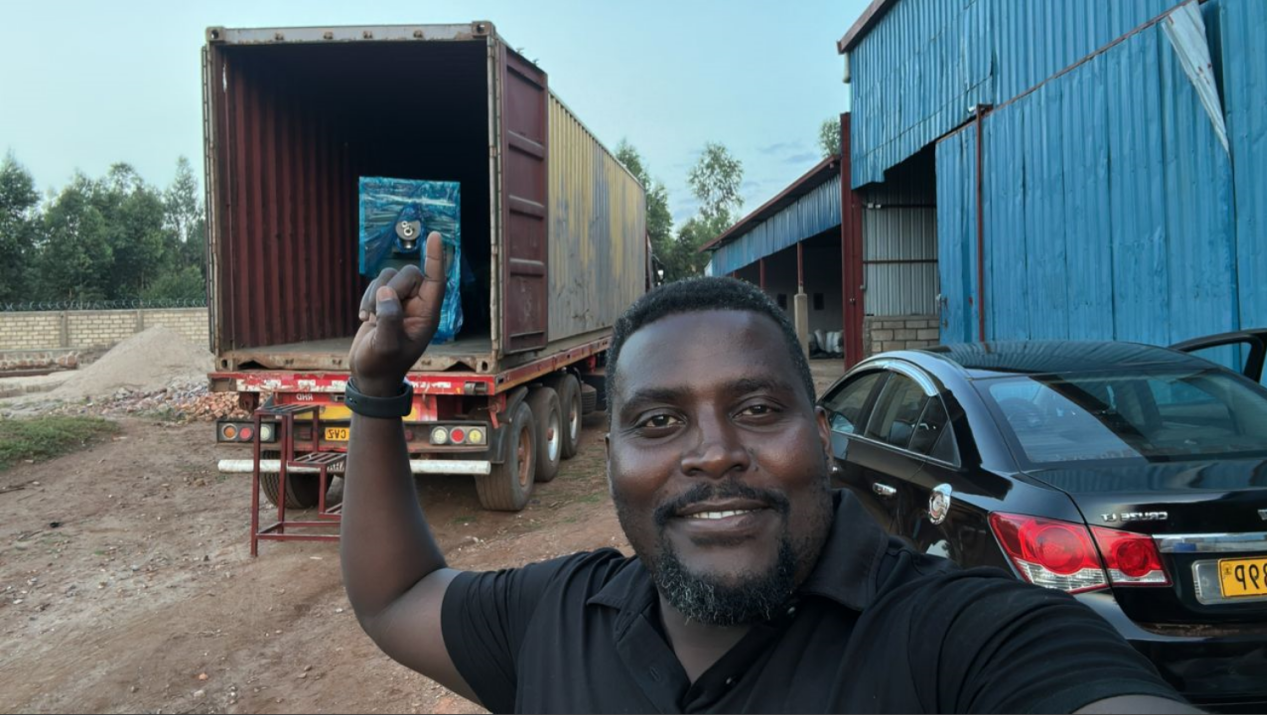

Practical Application: A client in Rwanda, for example, successfully integrated a thermal reactivation kiln into their operation. Proper training on temperature profiles and handling was key to maintaining the integrity of their carbon and achieving a closed-loop, economical process.

Chemical & Solvent Regeneration: Targeted Cleaning

For specific contaminants, a chemical wash can be more efficient than high heat. This method uses solvents, acids, or bases to dissolve or desorb the trapped pollutants.

Acid Washing (e.g., with HCl): Effective for stripping adsorbed heavy metals like lead or mercury.

Solvent Washing (e.g., with acetone or methanol): Ideal for recovering valuable volatile organic compounds (VOCs) from process streams.

Alkaline Washing (e.g., with NaOH): Used to remove certain acidic organic compounds.

Here, coal carbon again shows an advantage in durability. Its robust structure has excellent resistance to harsh acids and bases, allowing for aggressive chemical cleaning with less risk of degradation. Wood carbon is more susceptible to damage from strong acids or oxidants, which can hydrolyze the carbon structure itself. Chemical regeneration for wood carbon must use milder conditions.

Biological Regeneration: A Niche, Eco-Friendly Approach

In some wastewater treatment scenarios, a passive method called biological regeneration can be employed. Microbes are encouraged to colonize the carbon pore system and biologically degrade the adsorbed organic waste.

This method favors wood-based activated carbon. Its more open pore structure and surface chemistry are often more hospitable for microbial colonization and activity compared to the predominantly microporous network of coal carbon. While not suitable for all contaminant types and generally a slower process, it represents a low-energy option for specific biodegradable waste streams.

Choosing the Right Path for Regeneration

Your choice is guided by a simple flowchart:

What was adsorbed? For common organic pollutants, thermal regeneration is the default, high-efficiency choice.

What is the carbon type? For coal carbon, you can confidently use thermal or aggressive chemical methods. For wood/coconut shell carbon, prioritize precise thermal control or milder chemical options.

What are the operational goals? For solvent recovery or metal reclamation, targeted chemical regeneration is best. For a low-energy, biodegradable waste stream, biological methods might be explored.

The goal is to restore performance while preserving the carbon's physical integrity. By matching the regeneration method to both the contaminant and the carbon's material strengths, you can significantly extend its service life, turning it from a consumable into a reusable asset.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/how-to-regenerate-coal-and-wood-activated-carbon.html