How to Choose the Best Wood Charcoal Machine for High Efficiency and Low Cost

Choosing the right wood charcoal machine is crucial for ensuring high efficiency and minimizing costs in charcoal production. Below are key factors to consider when selecting the best machine for your needs.

1. Production Capacity and Automation Level

The capacity of a charcoal machine varies widely. Small-scale businesses may opt for batch-type carbonization furnaces, while large-scale operations benefit from continuous carbonization machines. Automated systems can further improve efficiency by reducing manual labor and increasing output consistency.

2. Energy Consumption and Fuel Efficiency

A high-efficiency wood charcoal machine should have optimized fuel usage. Look for machines with advanced thermal recovery systems, which reuse heat to minimize energy consumption. Some models also support multiple fuel options, such as biomass, gas, or electricity, to lower operational costs.

3. Raw Material Compatibility

Different machines are designed for different feedstocks. Ensure the machine you choose can handle your available raw materials, whether it is hardwood, softwood, sawdust, or agricultural waste. Some models feature adjustable carbonization parameters to accommodate diverse materials.

4. Carbonization Efficiency and Yield

The carbonization efficiency determines how much wood is converted into charcoal. Machines with higher efficiency produce more charcoal per unit of raw material, reducing waste and boosting profitability. Check the machine’s carbonization rate, retention time, and temperature control.

5. Durability and Maintenance Costs

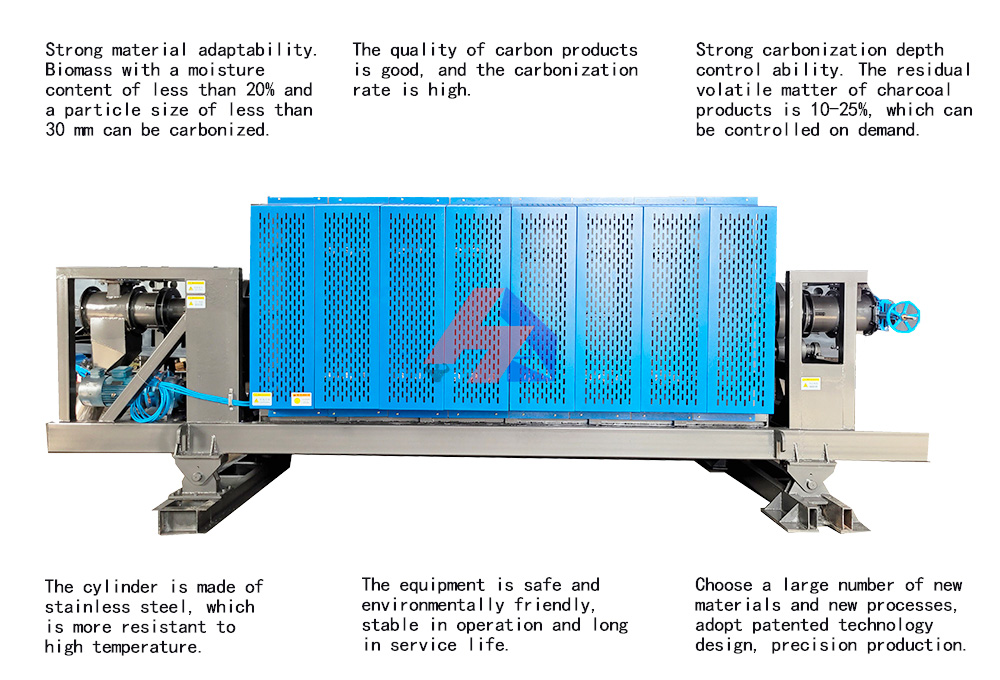

Investing in a durable machine reduces long-term operational expenses. For example, the charcoal machine produced by Hengju Machinery uses more durable materials and the latest design technology, making the charcoal machine produced by Hengju Machinery more solid. Hengju Machinery also provides more than one year of remote warranty service, reducing the customer's subsequent maintenance costs.

In general, if you want to choose an efficient and low-cost best charcoal machine, you also need to find a suitable charcoal machine manufacturing project. It is highly recommended that you choose Hengju Machinery. Our equipment is designed and built by professional engineers. If you have any questions about charcoal machines, please feel free to contact Hengju Machinery.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/how-to-choose-the-best-wood-charcoal-machine-for-high-efficiency-and-low-cost.html