The Difference Between Horizontal Carbonization Furnaces and Continuous Carbonization Furnaces

Choosing the right carbonization equipment is crucial when starting a charcoal production business. Among the many common equipment types, horizontal and continuous carbonization furnaces are the most representative. Understanding the differences between these two types of carbonization furnaces will help you make a more efficient and cost-effective choice for your production line.

1. Definition and Working Principle

A horizontal carbonization furnace is a batch-type equipment primarily used for small- to medium-scale charcoal production. It operates by loading biomass feedstock, such as sawdust, coconut shells, and wood chips, into a sealed furnace chamber and carbonizing them in an oxygen-deficient environment. After carbonization of a batch is completed, the furnace must be cooled and cleaned before the next production run can begin.

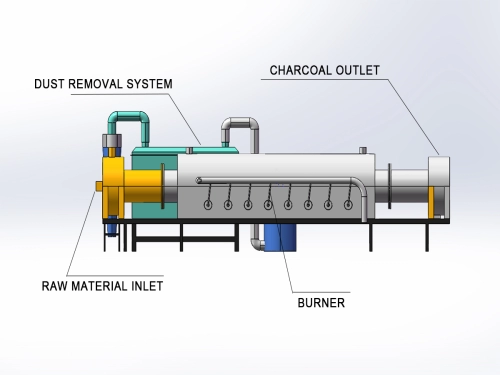

In contrast, a continuous carbonization furnace operates continuously, eliminating the need for downtime between batches. It utilizes an automated feeding and discharging system, with feedstock entering at one end and finished charcoal discharged at the other. This structure significantly improves production efficiency and operational stability.

2. Production Capacity

One of the main differences between horizontal and continuous carbonization furnaces is production capacity.

Horizontal carbonization furnaces are suitable for small- to medium-sized or pilot charcoal projects. Depending on the model and feedstock, each batch can produce approximately 200–800 kg of charcoal.

Continuous carbonization furnaces, on the other hand, are suitable for large-scale industrial production, processing several tons of biomass feedstock daily and meeting the needs of commercial charcoal production.

3. Energy Efficiency and Heat Utilization

Energy consumption is a key factor distinguishing the two types of carbonization furnaces. Horizontal carbonization furnaces require preheating, carbonization, and cooling for each batch, resulting in higher fuel consumption and wasted heat during downtime between batches.

Continuous carbonization furnaces, on the other hand, recycle the combustible gases produced by the carbonization reaction during operation for self-heating, significantly improving energy efficiency. Compared to traditional batch furnaces, they can save 30–50% in fuel consumption. Therefore, continuous carbonization furnaces are more energy-efficient, environmentally friendly, and economical in long-term operation.

4. Automation and Operation

Horizontal carbonization furnaces require manual loading and unloading, increasing labor costs and operating time. In contrast, continuous carbonization furnaces are equipped with an automated feed conveyor, carbonization reactor, and cooling system. Once started, the equipment can operate continuously for 24 hours with minimal human oversight.

This automation advantage makes continuous carbonization furnaces more suitable for industrial production operations with a stable raw material supply and high production demands.

5. Charcoal Quality and Stability

Both carbonization furnaces can produce high-quality charcoal, but continuous carbonization furnaces offer greater product consistency. Their automatic temperature control system and stable carbonization process ensure uniform carbon content and reduced impurities. Horizontal carbonization furnaces, however, rely on manual operation, which can lead to uneven heating and inconsistent carbonization.

6. Investment Cost and Applications

Horizontal carbonization furnaces are relatively affordable and easy to install, making them an ideal choice for start-ups or small-scale charcoal producers. They are also flexible and suitable for areas with limited electricity or space.

In contrast, continuous carbonization furnaces require a higher initial investment and more complex installation and commissioning, but they offer higher returns in the long run by saving fuel and labor costs.

In summary, if you're just starting out, need to test raw materials, or are only engaged in small-scale production, a horizontal carbonization furnace is a suitable choice. If you're looking for high output, stable operation, and long-term profitability, a continuous carbonization furnace will be more suitable.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/company-news/continuous-carbonization-furnaces.html